Project Details

Title of the Project:

Design and Development of Air Ventilated Air Bed for Hospitalized Patients

Name of the Students:

| Name | PRN No. | Exam Seat No. |

|---|---|---|

| Darshan Karanje | 0220190155 | B219113 |

| Sanket Hon | 0220190045 | B219093 |

| Shivraj Gursal | 0220190046 | B219094 |

| Shivroop Patil | 0220190190 | B219118 |

Name of the Mentor:

Dr. P.R. Hatte, Dean – School of Mechanical and Civil Engineering, MIT Academy of Engineering, Pune

Abstract:

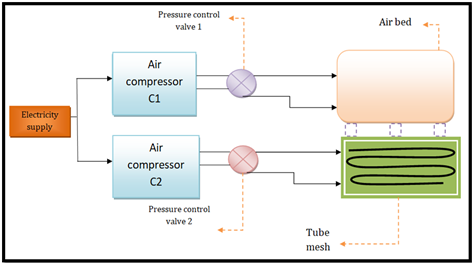

For hospitalized patients, proper ventilation constitutes one of the most important factors for their comfort. It is also one of the important methods for preventing various problems related to insufficient ventilation. Air-Ventilated Air Beds are used for delivering air to major parts of the body. This air bed is designed in such a way that the air is continuously ventilated throughout the body of hospitalized patient. It is especially useful for patients who suffer from diseases that make them bedridden or compulsory to spend long time in bed. Bedsores are usually caused by excessive heat generation between the bed and the patient. The main cause for bedsores is sweating, so air ventilation is provided in the system to avoid sweating and minimize the risk of bedsores. The components used are dual compressors, rubber tubes, flow control valves, and Anti-decubitus mattresses. The air is ventilated through the rubber tubes. The rubber tube mesh is placed above the mattress. First, the air is compressed in the two compressors which pass through the distribution manifold and further pass toward meshing. The tubes are modified by providing holes in them at a specified interval. The air from the compressor is flown through the pipes and then it passes through the holes in the pipes. The free flow of compressed air in a capillary tube brings down air temperature. In this way, the air is ventilated throughout the bed. By implementing the proposed solution bedsore can be prevented.

Image of Model/Block Diagram:

Fig. 1 – Block Diagram

Project Key Achievements:

- Appreciation received from Siemens India PVT. LTD.

- Project model is actually implemented and tested at Saiswami hospital, Kopargaon.

- Appreciation received from Saiswami hospital, Chandekasare, Kopargaon, Dist: Ahmednager.

- Received full project reimbursement of Rs. 6339/- from MIT Academy of Engineering, Pune.

Outcomes:

- The project will be an efficient solution for health issues occurring for a long time bed rest.

- Available equipments can be modified with affordable cost and for better results.

- Whole new system can be implemented in affordable cost.

- Whole hospital ward can be provided with system by connecting the tube mesh to a common supply line and pressure can be adjusted at bed station using valves.

- This will maintain a good health of patient and help in quick recovery.

Outcomes/Important Result:

Table No. 1: System Analysis

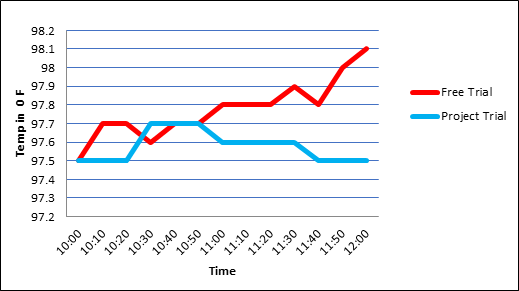

Process:

- Both trials (free and Project) was performed in the morning secession on alternate days in time slot of 10:00 AM to 12:00 PM. The readings are recorded after every 10 min. of time interval.

- For the free trial patient is bed rested freely/ in a conventional way. For project trial patient is supported with air compressors and tub mesh for ventilation.

- Free Trial Results are: air bed temperature is 97.1 0F, Body average temperature 96.38 0F with cloths, Body surface temperature 97.77 0F, at the end of trial.

- Project Trial Results are: air bed temperature is 96.4 0F, Body average temperature 96.40 0F with cloths, Body surface temperature 96.34 0F, at the end of trial.

Table 4 – Material Testing

| Sr. No. | Material. | Time duration (min.) | Initial Temp. (0 F) | Initial Temp. (0 F) |

|---|---|---|---|---|

| 1. | Wood | 3 | 84.4 | 83.8 |

| 2. | Steel | 3 | 84.9 | 83.9 |

| 3. | Ceramic | 3 | 84.9 | 84.2 |

Project Cost:

| Sr. No. | Bill name | Description | Amount |

|---|---|---|---|

| 1. | Air mattress | Air mattress along with compressor to provide compressed air in air bed, Invoice No.CS511, amount including GST. | 2100 |

| 2. | Airbed | Airbed along with compressor to provide compressed air in tube mesh, Invoice No. CA/1599, amount including GST. | 2240 |

| 3. | Infrared thermometer | No.1626, consist of thermometer for temp. Measurement. | 1999 |

| Total | 6339/- | ||

Motivations:

In the COVID-19 pandemic many patients have to take rest for more than 10 days and due to this the chances for causing bed sore to patients are high. Also, in the summer conditions patients are suffering from extensive sweating resulting in high chances of suffering from bed sore or from other skin diseases such as rashes on body. Here the main motivation for designing and developing air bed is to reduce bed sore and other skin diseases caused by not getting proper ventilation to the patients. In this project the ventilation is provided through the pipes which are embedded in the bed and the air is supplied by the compressors. The Anti- Decubitus used here also benefits in air circulation. In this way the problem of bed sore is reduced which is the main motivation of this project.

Project Challenges:

- Keeping the noise of compressor low while operation of air bed.

- Maintaining the required body temperature of patients.

- Avoiding any discomfort generated by the tubes used for ventilating the air bed.

- Identification of air leakage from the tube mesh.

- Maintaining uniform air flow throughout the air bed.

Conclusions:

- The bedsore problem can be eliminated/ minimized using this system.

- The designed system is efficient than present alternatives available in market.

- Engineering trial and error basis method can be used to resolve medical issues.

- Red chart line indicates the Airbed readings having temperature range of 97.5 0F minimum and 98.1 0F as maximum. If the chart line is observed then it showed that temperature is increasing with a step after a certain time interval. A step formation can be observed after 30 minute of time interval.

- While blue chart line indicates actual implementation of project and its minimum temperature is 97.5 0F and maximum is 97.7 0F. If chart line is observed it shows temperature got increased at first and then it achieves a constant stage. The chart shows a rise in temperature at the beginning and then it steps down to normal temperature and maintains a constant temperature of 97.5 0F.

- The conclusion from chart is that project implemented gives better results than previous system; system is successful to maintain a constant body temperature of patient.