Exploring the Benefits of Honours and Minor Degrees

Industry 4.0 is becoming more and more familiar, especially among students who are the future drivers of this technological revolution. But what exactly is Industry 4.0, and how is it changing the way we think about technology operations?

Let's gain a deeper understanding of Industry 4.0, including its history, the cutting-edge technologies it incorporates, and its significant effects on the technology industry.

Core Concept

The Fourth Industrial Revolution, or Industry 4.0, is the most recent phase in the development of industry and manufacturing. It is characterized by the integration of digital technologies into physical processes, creating a “smart” ecosystem where

- Machines,

- Devices,

- Systems

- Internet of Things (IoT): IoT-enabled machinery may talk to one another in a factory to maximize efficiency, anticipate maintenance requirements, and cut down on downtime.

- Artificial Intelligence (AI): AI plays a crucial role in making sense of the vast amounts of data generated by Industry 4.0 technologies. Artificial Intelligence (AI) can examine patterns, forecast outcomes, and even automate decision-making processes through machine learning.

- Big Data: The sheer volume of data generated in Industry 4.0 environments is staggering. Big Data technologies help in collecting, storing, and analyzing this data to extract valuable insights that drive business decisions.

- Cloud Computing: They enable businesses to access advanced computing resources without investing heavily in physical hardware.

are interconnected and can communicate with each other autonomously.

According to Global Market Insights (2025), the global Industry 4.0 market was valued at USD 149.2 billion in 2025 and is projected to reach USD 1.2 trillion by 2035, growing at a CAGR of 24%, highlighting the rapid global adoption of smart industrial technologies.

Historical Evolution from Industry 1.0 to Industry 4.0

To fully appreciate the advantages of Industry 4.0, it’s essential to understand the historical context. The journey began with Industry 1.0 in the late 18th century, which introduced mechanization through steam power.

Industry 2.0 followed in the early 20th century, bringing mass production and assembly lines, powered by electricity. Industry 3.0 emerged in the late 20th century with the advent of computers and automation, leading to more sophisticated and precise manufacturing processes.

Now, we are in the era of Industry 4.0, where the focus is on smart technologies that enable real-time data collection, advanced analytics, and automated decision-making.

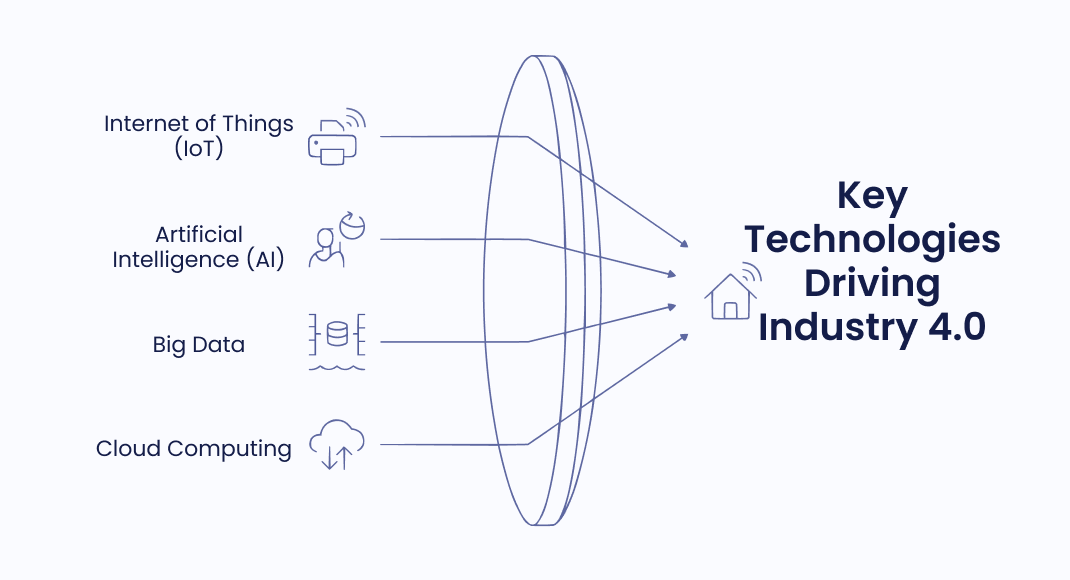

What are the key Technologies Driving Industry 4.0 ?

Several groundbreaking technologies are at the heart of Industry 4.0. Let's examine a few of the most significant ones in more detail:

Benefits of Industry 4.0 on the Technology Sector

Now that we have a basic understanding of what Industry 4.0 entails, let’s explore the significant benefits it brings to the technology sector.

1. Increased Efficiency and Productivity

One of the most significant industry 4.0 benefits is the dramatic increase in efficiency and productivity. Automation and real-time data analytics allow companies to streamline operations, reduce waste, and produce goods faster and more accurately. Smart factories, for instance, can automatically adjust production lines based on demand, ensuring that resources are used optimally.

2. Quality Improvement Through Technology

The impact of Industry 4.0 on business goes beyond just speed; it also enhances quality. With AI and machine learning algorithms continuously monitoring production processes, any deviations from the desired standards can be detected early.

3. Supply Chain Optimisation

Industry 4.0 also revolutionizes supply chain management. Businesses are able to anticipate possible delays, optimize logistics, and track materials and goods in real-time by integrating IoT devices across the supply chain. This level of visibility and control leads to more efficient operations and better customer satisfaction.

4. Application of Industry 4.0 in Technologies

The applications of Industry 4.0 are vast and varied, particularly in the technology sector. Here are some of the most exciting ways it’s being put to use:

5. Smart Factories and Connected Technologies

Smart factories are the epitome of Industry 4.0. In these environments, machines, systems, and humans work together in a connected ecosystem. Everything from production lines to inventory management is automated and optimized through real-time data. This increases output while enabling more adaptable and responsive manufacturing procedures.

6. Data Analytics and Predictive Maintenance

Data analytics is a game-changer in the technology sector. By analyzing data from IoT sensors, companies can predict when equipment is likely to fail and perform maintenance before a breakdown occurs. This approach, known as predictive maintenance, reduces downtime and extends the lifespan of machinery, ultimately saving costs.

7. Robotics and Automation

Robotics and automation are key components of Industry 4.0. Advanced robots can perform tasks with precision and consistency, often in environments that are hazardous to humans. Automation not only increases efficiency but also allows companies to scale their operations without a proportional increase in labor costs.

Conclusion

As students, understanding these concepts and staying informed about the latest advancements in Industry 4.0 is crucial for preparing to enter a workforce that is increasingly defined by these technologies. The future of technology is smart, connected, and incredibly exciting, thanks to Industry 4.0.

OUR RECENT BLOG