How is AI Transforming the Chemical Process Industry?

Introduction

Large-scale operations, complex reactions, and heavy reliance on human monitoring have traditionally defined the chemical process industry. Engineers have depended on conventional control systems, manual data collection, and routine procedures to manage plant operations for decades. While this approach has built the foundation of modern manufacturing, today’s fast-paced, data-driven world demands more, greater efficiency, higher productivity, and a more substantial commitment to sustainability. Industries are turning to cutting-edge technologies, especially Artificial Intelligence (AI), to meet these challenges. With the power to analyze large volumes of data, learn from patterns, and optimize operations in real time, AI is revolutionizing chemical engineering. As a leading chemical engineering college in Pune, MIT Academy of Engineering (MIT AOE) ensures students are equipped with the skills to thrive in this AI-driven era.

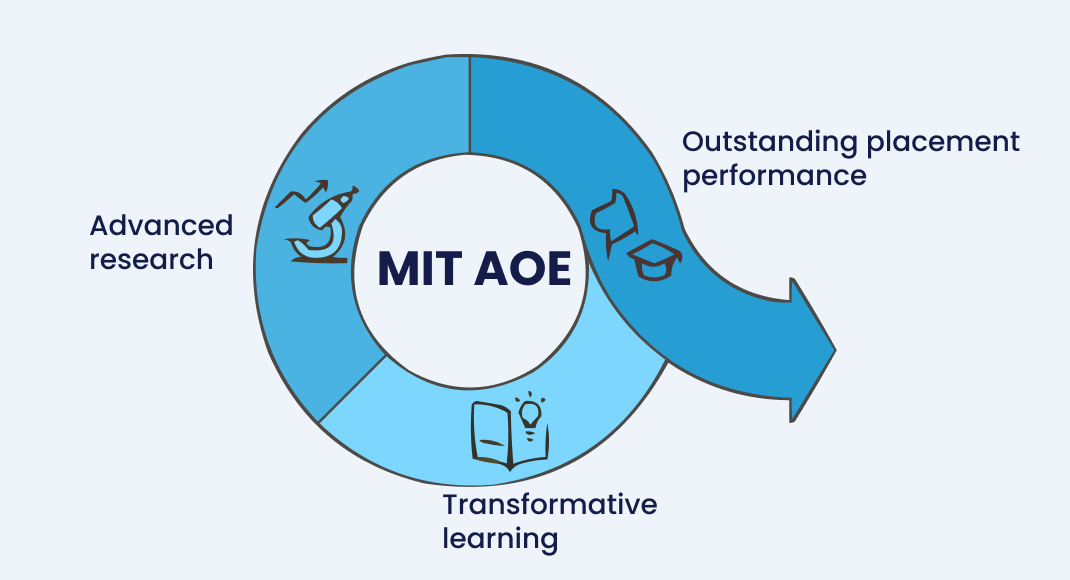

As an autonomous institute under Savitribai Phule Pune University (SPPU) and the recipient of several accolades including the Best Engineering College (Professional Courses) Award, MITAOE is home to

- Transformative learning

- Advanced research

- Outstanding placement performance

What is the role of AI in the chemical process industry?

In simple terms, artificial intelligence refers to the ability of machines to mimic human intelligence, learning, reasoning, and self-correcting. In chemical engineering, AI blends seamlessly with advanced computing, sensor technologies, and industrial automation to improve the performance of chemical plants.

AI doesn’t replace human engineers; instead, it enhances their capabilities. With predictive algorithms and real-time monitoring, engineers can identify inefficiencies faster, ensure product quality, and make proactive decisions. From improving yield to reducing energy consumption and minimising waste, AI offers transformative solutions across the entire value chain.

Key Applications of AI in Chemical Engineering

Process Optimization

- One of AI’s most powerful applications is optimizing chemical processes. Chemical plants produce enormous amounts of data from sensors and control systems. AI algorithms analyze this data to recommend optimal operating conditions—such as temperature, pressure, and flow rates—that can boost production efficiency while conserving resources.

- For example, machine learning models can simulate thousands of process scenarios to determine the most cost-effective pathway, all in real time. This leads to higher yields, lower emissions, and more innovative energy use.

Predictive Maintenance

- Equipment failure is one of the most significant risks in any chemical plant. Traditional maintenance practices involve scheduled check-ups or reacting to breakdowns. AI introduces a more intelligent approach—predictive maintenance.

- By monitoring machinery data like vibration, temperature, and performance trends, AI can detect early signs of wear and predict potential breakdowns. This allows engineers to perform maintenance exactly when needed, minimizing downtime, avoiding costly repairs, and extending equipment life.

Quality Control and Assurance

- Maintaining consistent product quality is non-negotiable in the chemical industry. AI helps by automating quality control processes. Computer vision and machine learning can inspect products, detect anomalies, and suggest real-time adjustments.

- Moreover, AI systems can analyze the impact of raw material variability, environmental conditions, or equipment performance on final product quality, allowing quicker corrective action and ensuring customer satisfaction.

Supply Chain and Inventory Management?

- Chemical industries often manage complex supply chains involving raw materials, production, storage, and distribution. AI streamlines this by forecasting demand, optimizing inventory, and improving logistics.

- For instance,

- AI can,Predict shortages,

- Recommend restocking schedules

- Optimize delivery routes based on real-time data.

This improves responsiveness, reduces waste, and lowers operational costs.

Artificial Intelligence (AI) is no longer a futuristic concept—it’s a powerful tool actively shaping the present and future of the chemical process industry. From predictive analytics and automated quality control to smarter supply chains, AI enables chemical engineers to innovate like never before.

We are committed to preparing our students for this transformative future at MIT Academy of Engineering, a top-tier chemical engineering college in Pune. Our programs integrate

- AI

- Machine Learning

- Digital Process Design

into chemical engineering education, equipping graduates to become leaders in innovative, sustainable industry practices.

As AI evolves, the chemical engineering field will only become more dynamic and exciting. The future belongs to those who can blend core engineering expertise with digital intelligence—precisely what MITAOEcultivates in every aspiring engineer.

OUR RECENT BLOG